Alkota Pressure Washers are long-lasting, American Made and dependable pressure washers. They have been an American based company for over 55 years originating in Alcester, South Dakota. Alkota's coils are made in South Dakota and are used in the entire family of hot water pressure washer.

Our machines see a wide range of different situations. From air that may contain airborne chemicals, like in a truck wash with high sodium levels found in hog operations. Dust and debris from a grain harvest to grinding dust and welding gases in a manufacturing facility. Construction environments, both on site and in shop getting tough messes taken care of in a timely manner to get back to the job needing to be done.

Even with all those challenges, there are two factors to face: Water and condensation from the environment. It creates quite a challenge.

Running cold water through a heated pipe creates sweat on the outside of the pipe, as well as inside the combustion chamber. The more efficient the heating is, the more condensation will happen, which will create a bigger issue. The air intake can become an obstacle as well, becoming wet and dirty, preventing efficient transfer of energy from the combustion chamber to the high-pressure water traveling through the pipe.

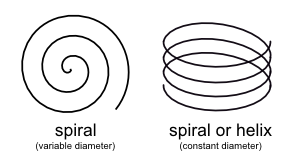

Alkota has found the solution. While most hot pressure washers use a horizontal spiral design, looking like a water hose coiled up. This configuration typically has many layers of the coil on top of each other. The problem is, the transfer of heat to the coil has inadequate ventilation and airflow around the pipe. The problem is that the coils on these washers are too tight.

Alkota's design is a helical configuration; it looks like a stretched spring. This spring or helical design is pictured as a large spring on the outside of multiple progressively smaller springs inside. This creates the heat absorbing while allowing for proper air flow in the combustion chamber.

Alkota has maintained the highest combustion efficiency in the industry. Other machines use a pancake coil; this condensed version has to have the circumference insulated because the design is over fired and has smaller gaps for the exhaust portion of the chamber.

1st: The outer wrapper of the unit can exceed 400 degrees creating a safety concern for machine operators.

Second, lack of proper ventilation for the exhaust. As the machine sees daily use, small air gaps in the coil will become smaller, and the accumulation of soot makes proper ventilation even harder. An efficient heated pressure washer needs three things: fuel, ignition, and free-flowing air, which is the critical variant here.

Safety

The outside of Alkota machines are cool to the touch, give it a touch! Typically, only 15-25 degrees above the outside temperature. Benefits are key here; operator safety is first and foremost when working with heat and pressure.

Combustion Efficiency

Our machines are designed to transfer heat with the high-pressure flow of water efficiently as possible. Using a helix coil design, we can keep cool on the outside but move BTU (heat) to focus on the temperature rise of the water, consuming most of the combustion gases, keeping things efficient.

Dependability

With our properly vented chambers and proper diesel or #1 fuel, soot build up is not an issue, thus, coil burn out is rare. The helix design is what creates efficiently, and dependability. EXP and Alkota back our coils with a 100% replacement in the first five years, and a prorated 50% replacement cost in the 6th and 7th years.

Express Pressure Washers has proudly sold and serviced Alkota Pressure Washers for over 35 years. We sell Alkotas because we know they are a great machine and built for the elements and hard work. Check out our website, give us a call at 507-583-2703 or come check out our Blooming Prairie showroom and see which Alkota will be best for your cleaning jobs. Express Pressure Washers: Driven by Service, Supported by Sales.